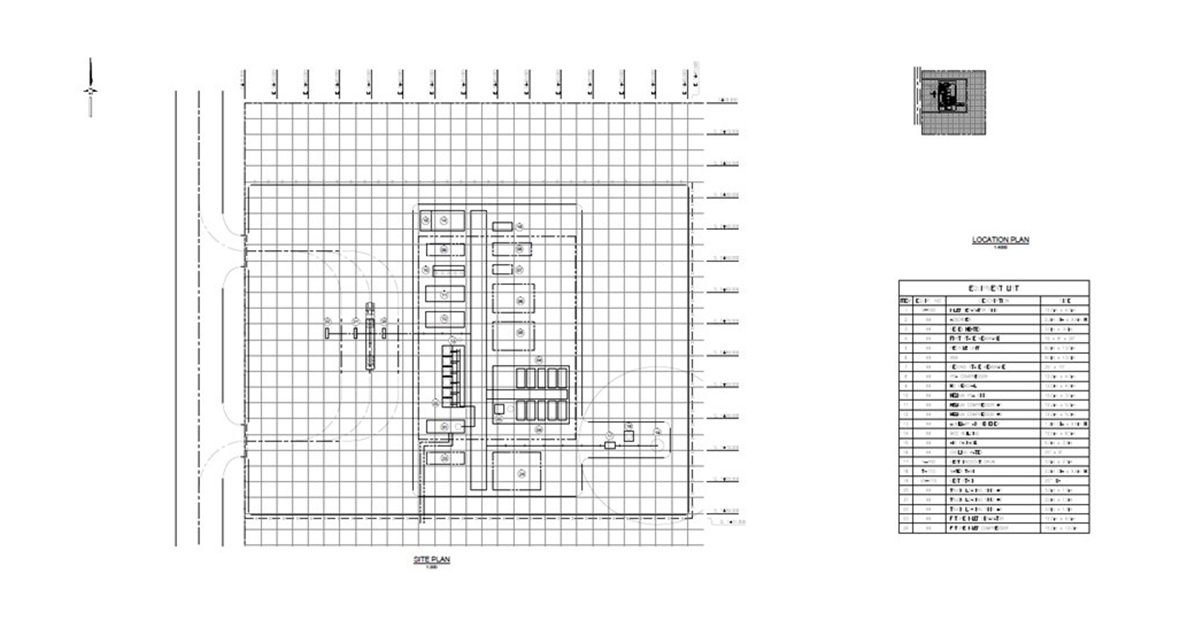

Helium Recovery Facility – Front-End Engineering & Design

Helium Exploration & Production Company | Battle Creek, SK

In the first phase, Journey partnered with the Client for initial scoping, design, and generating an AACE Class III cost estimate to achieve project sanction. Journey is now providing multidiscipline engineering and procurement services to integrate a 20 MMSCFD (throughput) helium recovery plant with 6 truck loading bays. This plant makes use of proprietary technology to purify a gas stream up to 99.999% helium as a saleable product. Helium is used in the medical industry (e.g., cooling MRI magnets or producing a heliox gas mixture), as an inert shield in arc welding, aerospace engineering (e.g., pressurizing fuel tanks of liquid fueled rockets), and in many other technology and scientific processes.

The Same but Different – Helium Recovery Requires a Specialized Skillset

This project is estimated to be finished in 2021. Once complete, this will be the largest facility of its kind in North America (using predominately membrane technology). The Journey team brings the right experience to the table, having completed similar projects in the past.