Landfill Optimization & Expansion

Journey partnered with the Client to provide engineering services for a Class II landfill. The first phase of the project was to review the current operation and aid in providing Best Practice recommendations and multi-year fill planning. The team then reviewed the current design and approved the waste height, existing berm structure and waste characteristics, and potential vertical expansion opportunities. Work included slope stability analysis of existing berm structure and slope stability analysis of the waste, modeling the increase in height above the berms.

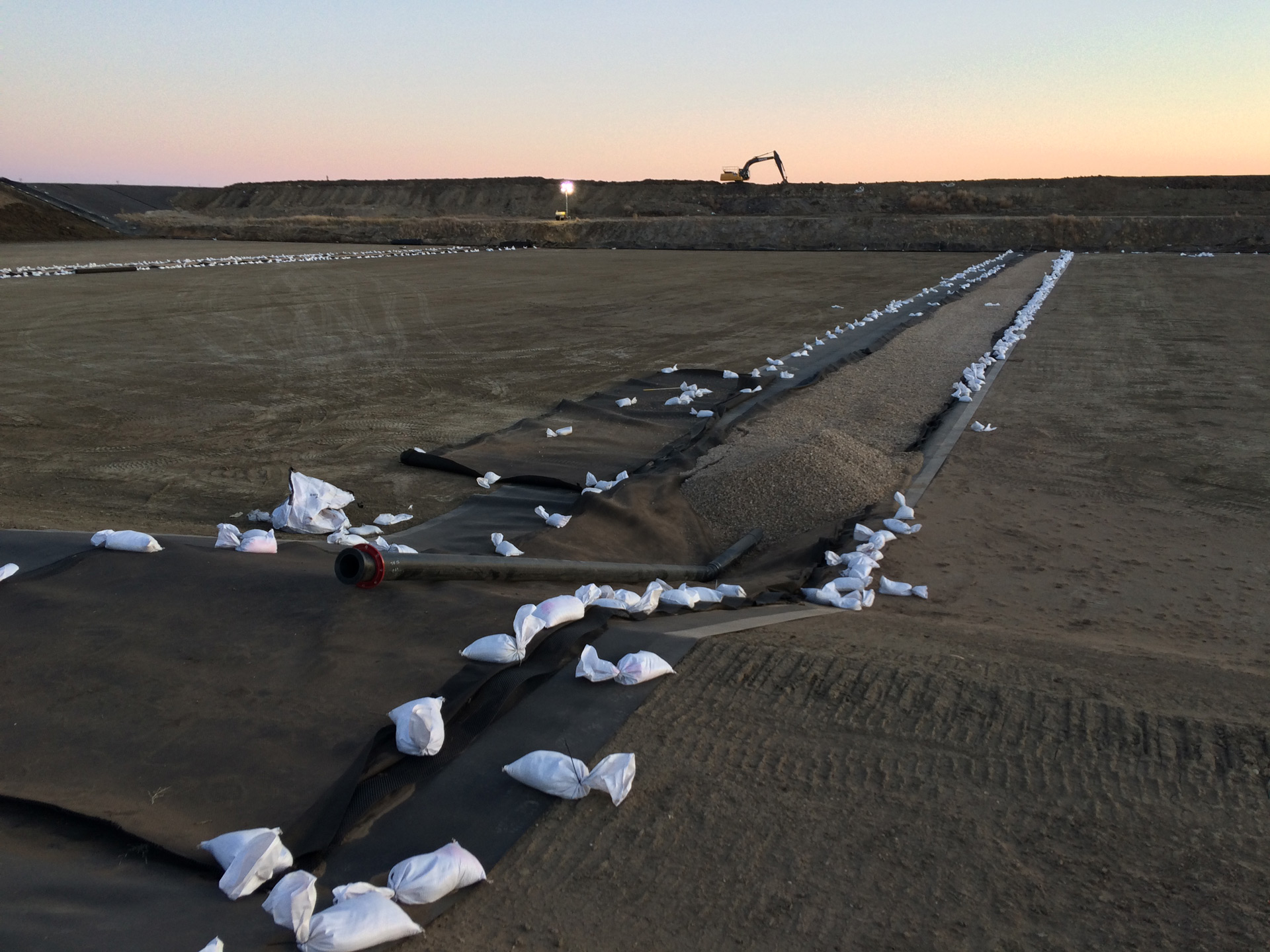

This was followed up with a complete a landfill lateral expansion. Work included a full design as well as construction management and QA/QC field inspection. During the construction phase of the project, work included earthwork grading for the landfill cell and leachate storage pond, tie-in to the existing landfill, and installation of a leachate collection system. The landfill containment system consisted of a compacted clay liner and a HDPE geosynthetic liner system.

Journey completed an extensive review of the Client’s operation practices and made recommendations for improvements. Once implemented, the Client saved over $200,000 a year in operating expenses, removing the need to install rig matting for landfill access. Also, Journey’s recommendations increased overall leachate management capabilities and waste stability with better placement practices.

The landfill cell expansion was completed in 2017. During construction there were challenges related to tying into the existing landfill and existing infrastructure. Journey worked with the Client and Contractor to resolve these challenges with practical, realistic solutions without compromising the performance of the landfill and still achieving all the requirements of Operations approval.

An example of this practical solution approach was the development of an interim Landfill Water Management Plan that was put in place to ensure adequate environmental protection until the leachate storage pond can be completed and put into service; it contained and managed 1,600 m3 of water.