Helium Recovery & Purification

Our team is tried and tested. A niche business like helium recovery and purification typically means fewer experienced teams; our team has experience in both fractional distillation and membrane technologies. Our engineers are among the best in the field, both in terms of complex process understanding as well as construction and commissioning support. You will achieve your schedule goals with our consistent project execution process, just ask our existing clients for proof.

As you embark on your helium journey, you will encounter some of the idiosyncrasies of this space, including proprietary technologies and large firms without a solid understanding of your local environment and unique properties of the element in question.

We have taken an 85% complete project in Wyoming and made it work and also built greenfield facilities with no prior infrastructure. Let our experience be your guide.

Liquid helium is the professional lifeblood of North America’s discovery and innovation landscape. As an inert gas, it has the lowest boiling point of any element, and it has many uses in the medical, military, and scientific fields. Helium is a product of the radioactive decay of elements like uranium and most of it actually diffuses through the earth’s crust and is lost into the atmosphere. It is possible to trap a small amount of helium underground and recover it via natural gas extraction.

While helium is a scarce and non-renewable resource, global demand is increasing. As that demand continues to rise, new helium sources must be developed. Journey has the perfect experience to help you start, expand, or optimize your helium recovery facility.

We can support you in:

- Technology assessments in both the fractional

distillation and membrane technology space - Feasibility, Conceptual, or Pre-FEED studies including Business Case Support

- Regulatory Support in Western Canada and many US states

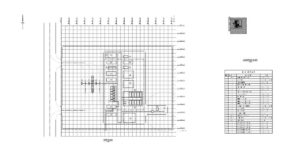

- Front-End Engineering and Design (FEED) or Preliminary Design including Cost Estimation

- Detailed Design

- Hazard and Operability Studies (HAZOPs)

- Project Management including Project Controls and Scheduling Support

- Supply Chain (SCM), Procurement, Vendor Management, and Pre Qualification

- Field Inspection and Quality Assurance and Quality Control (QA/QC)

- Maintenance and Operations Support including Management of Change (MOC) and Sustaining Capital Management

Related Helium Recovery & Purification Projects:

Cadillac Train 2 Helium Purification Facility

As the world continues to grapple with major risks to other global sources of helium, Journey Engineering (Journey) was proud to support North American Helium (NAH) with the successful completion of their …

Read MoreCO2 Sales Stream FEED

This project is meant to recover a vented carbon dioxide (CO2) waste stream and turn it into a salable product. The design will compress the waste stream before liquifying and purifying the …

Read MoreGas Gathering System for Helium Extraction

The Mankota gas gathering system consists of roughly 13 km of 6” pipeline, transporting raw gas from new well sites to an existing helium extraction plant. The project is located approximately 6 …

Read MoreHelium Enhancement Feasibility Study

Journey investigated the cost & feasibility of the installation of a helium liquefier in Western Canada. This front-end engineering and design (FEED) study began in July and finished the following month. The …

Read MoreHelium Recovery Facility – Detailed Design & Construction Support

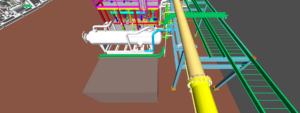

The Journey team brings the right experience to the table, having a background in both cryogenic distillation and membrane helium facilities.

Read MoreHelium Recovery Facility – Front-End Engineering & Design

In the first phase, Journey partnered with the Client for initial scoping, design, and generating an AACE Class III cost estimate to achieve project sanction.

Read MorePower Generation – FEED Study

After the construction and commissioning of the Battle Creek Helium Recovery Plant in Saskatchewan, efforts were undertaken to explore the viability of generating onsite electrical power through the use of the high-pressure …

Read MoreRegenerative Thermal Oxidizer

After the Battle Creek gas plant was constructed and put into operation, there was a desire to reduce greenhouse gas (GHG) emissions from the waste stream not normally considered combustible. While it …

Read More