Process Engineering

Aligns the Other Disciplines – You Need the Right Expert as Your Guide

If you’ve ever struggled with a challenging process design basis or a complex optimization problem, you’ll understand the importance of engaging the right process team as your guide.

The Journey Approach

1

Our goal is always to see a project through to commissioning and ensure it operates the way it was designed – and with safety in mind.

2

Our engineers are among the best in the field, both in terms of complex process understanding as well as construction and commissioning support.

3

Optimizing an existing plant is often much more difficult than designing new. Our engineers bring the depth of experience with ageing assets – just ask our current clients!

We can support you in:

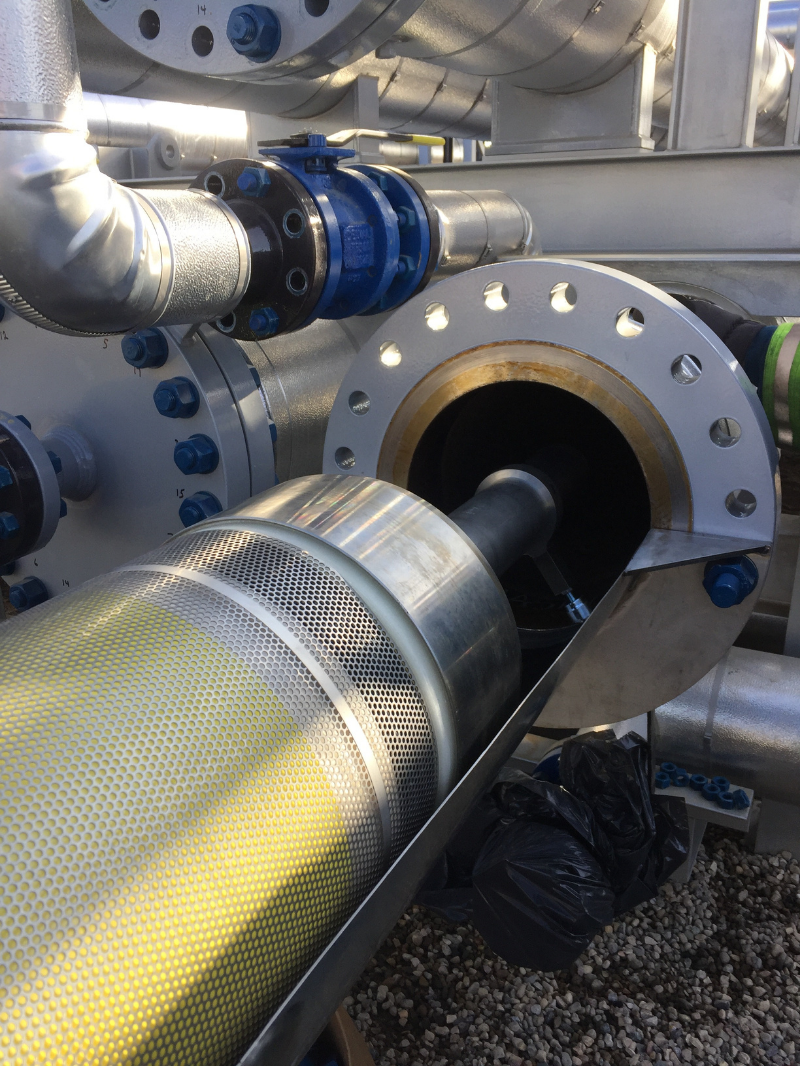

In the core of our multi-discipline engineering services, our process engineering group has the practical knowledge and experience in fluid mechanics and industrial process plant designs.

Our engineers are often consulted at the study phase to help with the project understanding and optionality to align the opportunity and project economics. Their expertise and leadership continue through the front-end engineering design and into detailed design. They have worked on pilot or proof-of-concepts with new/existing technologies and also with plant turnarounds, plant decommissioning, or re-purposing/relocation.

Our expert team with multi-year experience has designed and built assets for both the upstream and midstream sectors, published technical papers, and supported the development of proprietary technologies.

- Conceptual Design, Pre-FEED, and Front-End Engineering Design (FEED) Studies

- Process Flow Diagrams (PFDs)

- Piping and Instrumentation Diagrams (P&IDs)

- Process and Flare Studies

- Equipment & Vessel Sizing, Design, and Selection

- Process Confirmation and Due Diligence Checks

- Facility Troubleshooting and De-Bottlenecking

- Hazard Identification (HAZID), Hazard & Operability (HAZOP), Layer of Protection Analysis (LOPA), Process Hazard Analysis (PHA) Studies

- Other Safety Studies

- Operator Training

- Start-up and Commissioning Support

Technologies we are familiar with:

- Natural Gas Sweetening using amines, such as MDEA, DEA, DGA, MDEA, as well as branded blends including Selexol, Flexsorb, HS-101, and others

- Sulphur Recovery units using the base Claus process with modifications and tail gas units such as CBA, SUPERCLAUS, Sulfreen, and MCRC; wet processes such as Lo-Cat and Merichem

- Scavenger technologies (both dry and wet) for smaller removal requirements

- Hydrocarbon dewpoint processes such as silica gel, mechanical refrigeration, expanders, and solvent extraction

- Water dewpoint processes such as molecular sieves, silica gel, TEG dehydration, and deliquescent removal

- Membrane separation technologies and the associated pre-treatment needs

- Downstream product enhancement such as custom product blending and product fractionation

Partner with us

to build assets that work.

Related Process Engineering Projects:

CO2 Sales Stream FEED

This project is meant to recover a vented carbon dioxide (CO2) waste stream and turn it into a salable product. The design will compress the waste stream before liquifying and purifying the …

Read MoreGas Gathering System for Helium Extraction

The Mankota gas gathering system consists of roughly 13 km of 6” pipeline, transporting raw gas from new well sites to an existing helium extraction plant. The project is located approximately 6 …

Read MoreHelium Enhancement Feasibility Study

Journey investigated the cost & feasibility of the installation of a helium liquefier in Western Canada. This front-end engineering and design (FEED) study began in July and finished the following month. The …

Read MoreHelium Recovery Facility – Detailed Design & Construction Support

The Journey team brings the right experience to the table, having a background in both cryogenic distillation and membrane helium facilities.

Read MoreHelium Recovery Facility – Front-End Engineering & Design

In the first phase, Journey partnered with the Client for initial scoping, design, and generating an AACE Class III cost estimate to achieve project sanction.

Read MoreOil Blending Optimization

In order to protect Operations personnel from process upsets and maximize facility economics, a lean and practical solution was required. The Journey Team worked with the Client’s Engineering

Read MoreOil Blending Optimization Front-end Engineering & Design (FEED)

The client handles several hundred thousand barrels per day of crude oil and other hydrocarbon products through their Edmonton and Hardisty Terminals and is constantly looking to maximize oil blending opportunities. They …

Read MoreRail Transloading Crude Oil & Butane

This project involved adding a track to the existing track system, including switches, lighting, grounding, grading, drainage, and protection for the undergrounds.

Read MoreRegenerative Thermal Oxidizer

After the Battle Creek gas plant was constructed and put into operation, there was a desire to reduce greenhouse gas (GHG) emissions from the waste stream not normally considered combustible. While it …

Read MoreSatellite Battery Upgrade

Our client required a practical, cost effective solution to maintain operations when their producing wells were left stranded by the suspension of two large gas plants in the area. The solution

Read More