Mechanical Engineering

Your Project Integrator

Have you struggled with over-engineered designs or impractical solutions?

The Journey Approach

1

Fit-for-purpose designs with a prime focus on constructibility and operability.

2

Our engineers are among the best in the field, both in terms of complex technical understanding as well as construction and commissioning support.

3

Cohesive teams who respond to site-specific challenges and are ready to take advantage of cost or schedule saving opportunities.

We can support you in:

A critical part of our multi-disciplined engineering services, our mechanical engineers work in sync with our other disciplines to provide a fully integrated service.

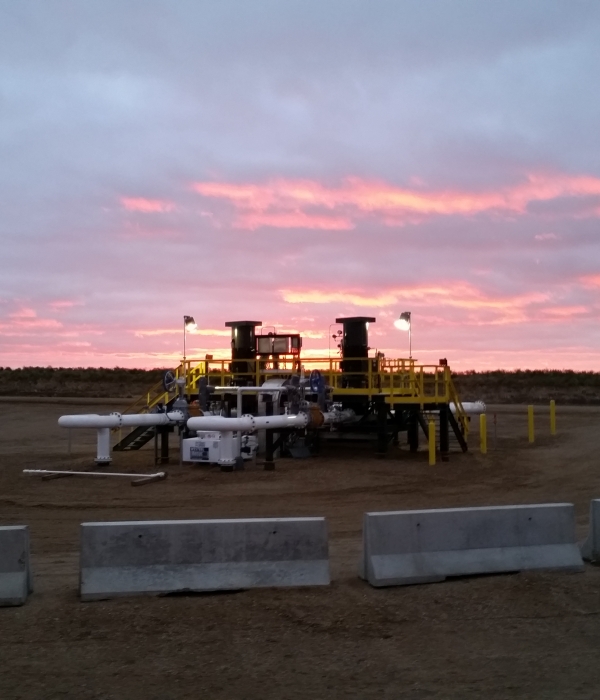

The mechanical engineering team participates in all phases of the project from conceptual studies through to detailed engineering, construction, start-up and commissioning, and turnover to operations. Our team is practiced in the areas of Oil & Gas Facilities, Helium Plants, Utility Systems, and Mechanical Design and Analysis. Our team believes in the mantras of fit-for-purpose designs and avoiding the traps of over engineering designs without compromising safety, constructibility, and operability.

This discipline is also a foundation for future project engineers that chose to move from the discipline and into the project practice. Journey looks to attract candidates from University co-op programs, Engineers in Training (E.I.T.s), as well as junior and intermediate engineers to provide career options to these individuals.

Our expert team with multi-year experience has designed and built assets for both the upstream and midstream sectors and supported the development of proprietary designs in Clean Technology.

- Mechanical Systems and Materials, Technical Selection, Sizing, and Equipment Evaluation

- Equipment Drawings, Piping & Instrumentation Diagrams (P&IDs), and

General Arrangement (GA) Drawings - Equipment Work Packages (EWPs)

- Equipment Datasheets and Lists

- Material Requisitions (MRQs), Technical Bid Evaluations (TBEs), and Purchase Orders (POs) for Equipment and Equipment Packages

- Vendor Drawing Reviews following Applicable Codes and Standards

- Construction Work Packages (CWPs)

Our mechanical engineers work hard to continually develop the skillset required to manage successful projects and stay sharp through certified external training. We know from experience that one size does not fit all and therefore our teams and the tools they use are configured to individual projects to best meet the needs of that client and project.

Call us today! We are always happy to hear form current and prospective clients to help brainstorm and plan their next project, no matter the size.

Partner with us

to build assets that work.

Related Mechanical Engineering Projects:

Cadillac Train 2 Helium Purification Facility

As the world continues to grapple with major risks to other global sources of helium, Journey Engineering (Journey) was proud to support North American Helium (NAH) with the successful completion of their …

Read MoreCO2 Sales Stream FEED

This project is meant to recover a vented carbon dioxide (CO2) waste stream and turn it into a salable product. The design will compress the waste stream before liquifying and purifying the …

Read MoreGas Gathering System for Helium Extraction

The Mankota gas gathering system consists of roughly 13 km of 6” pipeline, transporting raw gas from new well sites to an existing helium extraction plant. The project is located approximately 6 …

Read MoreHelium Enhancement Feasibility Study

Journey investigated the cost & feasibility of the installation of a helium liquefier in Western Canada. This front-end engineering and design (FEED) study began in July and finished the following month. The …

Read MoreHelium Recovery Facility – Detailed Design & Construction Support

The Journey team brings the right experience to the table, having a background in both cryogenic distillation and membrane helium facilities.

Read MoreHelium Recovery Facility – Front-End Engineering & Design

In the first phase, Journey partnered with the Client for initial scoping, design, and generating an AACE Class III cost estimate to achieve project sanction.

Read MoreOil Blending Optimization

In order to protect Operations personnel from process upsets and maximize facility economics, a lean and practical solution was required. The Journey Team worked with the Client’s Engineering

Read MoreOil Blending Optimization Front-end Engineering & Design (FEED)

The client handles several hundred thousand barrels per day of crude oil and other hydrocarbon products through their Edmonton and Hardisty Terminals and is constantly looking to maximize oil blending opportunities. They …

Read MorePower Generation – FEED Study

After the construction and commissioning of the Battle Creek Helium Recovery Plant in Saskatchewan, efforts were undertaken to explore the viability of generating onsite electrical power through the use of the high-pressure …

Read MoreRail Transloading Crude Oil & Butane

This project involved adding a track to the existing track system, including switches, lighting, grounding, grading, drainage, and protection for the undergrounds.

Read MoreRegenerative Thermal Oxidizer

After the Battle Creek gas plant was constructed and put into operation, there was a desire to reduce greenhouse gas (GHG) emissions from the waste stream not normally considered combustible. While it …

Read MoreSatellite Battery Upgrade

Our client required a practical, cost effective solution to maintain operations when their producing wells were left stranded by the suspension of two large gas plants in the area. The solution

Read More